Diving Services

West Squadron Marine Services Pte Ltd has a pool of highly qualified professional diver who comes from varied background and work experiences. Our Diving Superintendent was trained all form of underwater work in United States. Our divers are commercially well-trained and possess accumulated commercial underwater ship maintenance experiences which are the essence of our company to provide top quality services, work assurance and excellent safety record.

Our scope of professional diving services (24/7 operations: 24 hours a day & 7 days a week)

- Classification society in-water CCTV survey / visual inspection

- Underwater hull cleaning, inspection and repair

- Underwater propeller polishing, cutting and trimming

- Underwater cutting, blanking, patching, plugging and welding

- Installation of cofferdam and anodes

- Seabed survey

- Deep and shallow water diving

- Other underwater services

Details of written report with photographic and/or video will always submitted in DVD format upon completion of each diving operations. The stated information on report will enable the reader to view the results after job completed.

Hull Inspection

Purpose of Hull Inspection:

To inspect / ascertain the condition of submerged hull below waterline to identify potential problem areas in order for remedial action to prevent deterioration or further damage.

Method A

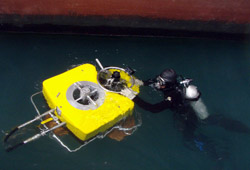

Inspection with Close Circuit Television Video (CCTV)

Provide “real time” visual/viewing. This CCTV survey conducted in the presence of ship representative and/or class surveyor to visual/view condition of ship through CCTV monitor on board diving workboat directly. Result of inspection supported with video recorded and still photograph in DVD format.

Method B

Inspection with still photograph

Generally, the ship representative and/or class surveyor are not required to be present during the inspection. Result of inspection supported with still photograph only.

Hull Cleaning

Marine growth is a problem for any vessel.

Purpose of hull cleaning:

To remove the marine growth such as sea algae, barnacle which is define as a hard shell attached itself to the bottom of hull and this increase water resistance and reduce speed and performance of the vessel.

Our advanced equipment has its capabilities to clean various type of marine growth including stubborn and hard marine growth without damaging paintwork of vessel.

Before Cleaning

After Cleaning

Propeller polishing, cutting and trimming

The propeller efficiency deteriorates in time due to the increasing surface roughness and also with the growth of marine fouling.

The propeller roughness significantly affects ships such as high fuel consumption, low speed and less power performance.

Purpose of propeller polishing:

Propeller polishing is an economic and cost effective method to maintain the good performance of vessel.

After polishing, the surface condition will be checked using the Rubert Comparator Scale which consists of 6 specimens reflect exact replicas of the surface roughness of propeller blades.

Before polishing

After polishing

Purpose of underwater cutting and trimming:

To reduce load of main engine due to damage of propeller blades causes by hitting hard object or ship grounding.

To balance the blade rotation and eliminate vibration effect of the propeller and achieve required speed.

Purpose of grinding:

To eliminate the sharp edge and grind smooth to profile after cutting and trimming.

Underwater Welding and Repair Wet Welding is to perform underwater welding and repair of vessel.

Purpose of underwater welding and repair wet welding

Damage and/or corrosion submerged hull shell plating of ship required temporary repair such as welding doubler plate etc to prevent further deterioration damage on affected areas.

Additional protection of repair job with deposit of underwater epoxy to reinforced the affected areas and protects the weld seam from corrosion.

Purpose of inspection and removal of entanglement:

To detect any abnormalities of rope guard and propeller shaft such as rope entanglement which may result damaging of stern oil seal.